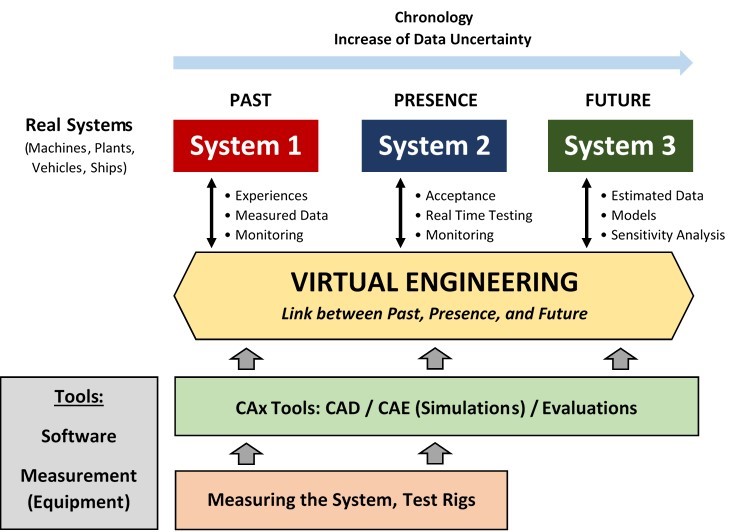

These are the advantages of the virtual development process („VIRTUAL ENGINEERING“):

An important principle of such a work: It is not primarily about the advertising effective and colorful presentation of R&D efforts in impressive 3D presentations. In the first step, I always prefer structured development planning with powerful simulation tools as aids. This involves an engineering evaluation and practical assessment of the results with regard to the specified product development and product optimization. 3D computer models are certainly useful, but they do not replace the main work of the development engineer.

Use my engineering services to create and realize your own virtual engineering environment: this is the so-called „Virtual Engineering On Demand“.

I would like to get into contact with you. Ask for a non-binding customer presentation realized by an online meeting. In many cases I take the opportunity to involve further external partners in such projects (like design and development engineering offices or measurement service providers).

Analysis and simulation of torsional vibrations in drive systems (drivelines, powertrains) of rotating machinery, vehicles, ships. Learn more …

Analysis especially of lateral and flexural vibrations including a stability analysis of rotor bearing systems in rotating machinery supported by the software ARMD. Learn more …

Publications by Dr. Andreas Laschet: technical papers in journals, conference papers, book contributions. Learn more …

International engineering seminars in close cooperation with Concepts NREC (US). More information available: Detailed Seminar Program & Online Registration …

You may download further information (PDF):

I would like to offer my best custom-tailored engineering service concerning your current project. Please send me your inquiry (submission of your inquiry).

Download (PDF):

Do you already know the HELP AREA (Support - Questions & Answers)?

This link will take you there immediately:

| Cookie | Description |

|---|---|

| Necessary / Notwendig | |

| CookieLawInfoConsent | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| cookielawinfo-checkbox-analytics | Set by the GDPR Cookie Consent plugin, this cookie records the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-performance | Set by the GDPR Cookie Consent plugin, this cookie stores the user consent for cookies in the category "Performance". |

| viewed_cookie_policy | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| cookielawinfo-checkbox-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-non-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| Non Necessary / Nicht notwendig | |

| test_cookie | This cookie is set by doubleclick.net. The purpose of the cookie is to determine if the users' browser supports cookies. |

| Analytics / Analytik | |

| _ga_* | Google Analytics sets this cookie to store and count page views. |

| _ga | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, camapign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assigns a randoly generated number to identify unique visitors. |

| _gid | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

| Performance / Leistung | |

| _gat | This cookies is installed by Google Universal Analytics to throttle the request rate to limit the colllection of data on high traffic sites. |

Phone: +49 2268 901650 • Email: info@laschet.com • Web: www.laschet.com

HOME – ABOUT ME – ENGINEERING – WEBINARS – SEMINARS – TECHNICAL CONSULTING – CONTACT

Site Notice – Privacy Policy – Information Obligation – Cookie Manager – Legal Notices